Home » Valves » V-Ball Valves »

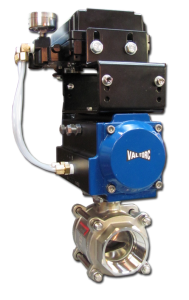

V BALL VALVE (STAINLESS STEEL)

Rating: 5/5

Manufacturer: Valtorc

Product Description, Dimensions and Specifications PDF

Series VP-1000 (Stainless Steel V-Port Ball Valve)

V-Ball and V-Port ball valves are an ideal solution to control flow through a pipe. V-Ball valves are a great solution to modulate flow and can be actuated. This series of V-Balls are made from 316 stainless steel and are configurable in almost any industry. These valves are both lighter in weigh and more durable than standard valves sold overseas.

V-SEAT, V-SLOTTED, V-BALL CHARACTERIZED SEAT CONTROL VALVES

We have a complete line of V-Port Ball Valves, V-Ball, V-seat and slotted seat control valves providing precision throttling control for a wide range of applications. As with our standard ball valves, V-characterized seated valves offer equal percentage flow characteristics. The slotted seated valves have an inherent linear flow characteristic.

We have a complete line of V-Port Ball Valves, V-Ball, V-seat and slotted seat control valves providing precision throttling control for a wide range of applications. As with our standard ball valves, V-characterized seated valves offer equal percentage flow characteristics. The slotted seated valves have an inherent linear flow characteristic.

OFFERED IN FLANGED, NPT (THREADED) SOCKET WELD, BUTT WELD AND TRI CLAMP

OFFERED IN FLANGED, NPT (THREADED) SOCKET WELD, BUTT WELD AND TRI CLAMP

- V-Ball valves available between 1/4" and 6" in size

- Available in: ANSI flanged, NPT (threaded) socket weld, butt-weld and tri-clamp

- V "notch" available in 30, 60 and 90 degree options

- Available in manual or actuated mode

- Precise flow control in any industry

- Light weigh, up to 30% lighter than comparable valves

- Low cost with comparable valves of similar pressure drops

- Low Flow Control - Cv as low as 0.07

- High temperature ratings (up to 1000F in some valves)

- The V "notch" allows for much freer flow with better characteristics

- Valve eliminates the need to replace a seat

- All V-Ball valves are manufactured and tested in America

WATCH OUR ACTUATED V-BALL VALVE VIDEO:

CALCULATE THE VALVE SIZE

With the above information, the following steps are used to correctly size a valve in a piping system.

- Cv value is obtained by using the appropriate ANSI/ISA–75.01.01 flow sizing formula or computer aided flow control sizing program that is based on these formulas.

- Cavitation is checked by using the FL value (Liquid Pressure Recovery Factor), and the expansion factor needed for compressible fluids is obtained using the values (Pressure Drop Ratio Factor). Both values are found in the Cv charts supplied on the following pages.

- Select a nominal valve size from the Cv charts based on the calculated Cv.

V-Port Ball Valves: Select a valve which offers calculated Cv for the minimum and maximum flow between 20% to 80% of port opening.

Round Port Ball Valves: Select a valve which offers calculated Cv for the minimum and maximum flow between 30% to 80% of port opening. - Select the valve type (flanged, threaded or welded) and materials of construction.

- Valtorc recommends RTFE valve seats for V-Ball Control Valve applications.

- Select the actuator – for Actuator Sizing please see our actuator product pages and IOM doucments.

V-BALL BENEFITS:

- Quality product

- Simplicity - Very low maintenance costs

- Tight Shutoff - Exceeding Class VI and bubble-tight

- High Rangeability - Repeatable control through 95% travel

- Low Cost - Purchase price is substantially lower

- Low weight - about 30% lighter than globe control valve

- Compact Size

- Shearing Action

- Low Flow Control - Cv as low as 0.07

- Flexible CV

- Erosion Resistant

- High Pressure Drop

- High Temperature - Up to 1,000°F

CREDIT APPLICATION

Please fill out our credit application for purchase orders and net terms. Download here

DISTRIBUTORS WANTED

Apply to become an official protected distributor. Click here to fill out our distributor application. (Online Form)

VALVE PRODUCT CATALOG

New! Download our 2018 product overview catalog or call us to request a copy. Click here to download (PDF)